The future of design deliverables is here, and its name is 3-D!

Civil Design Software has advanced to a point that 3-D design deliverables are now a reality. Brainstorming sessions such as the Every Day Counts (EDC) Innovations have brought together DOTs, consultants and contractors to develop new, innovative and efficient methods of delivering, scheduling and constructing civil projects.

The Ohio Department of Transportation invited E.L. Robinson Engineering (ELR) to take part in the EDC program due to our experience in 3-D modeling. ELR was teamed with other firms and contractors to come up with 3-D deliverables that would enable the contractor to automate project construction through 3-D modeling and GPS instrumentation. Contractors can input the consultant developed surface models into construction equipment GPS instrumentation. This instrumentation provides a heads-up display (HUD) of the job surfaces as the machines grade through the earth. And, with a flip of the switch, the computer can take control of the earthmoving blades, automating the grading process.

E.L. Robinson Engineering was the first firm to provide ODOT a 3-D model deliverable for a project (FRA-71-5.29) to be used for construction. This deliverable was based off the EDC program recommendations which included the following formats:

- 3-D surfaces – LandXML

- 3-D meshes

- 3-D contours

- 3-D line strings (break lines)

- 3-D DGN files

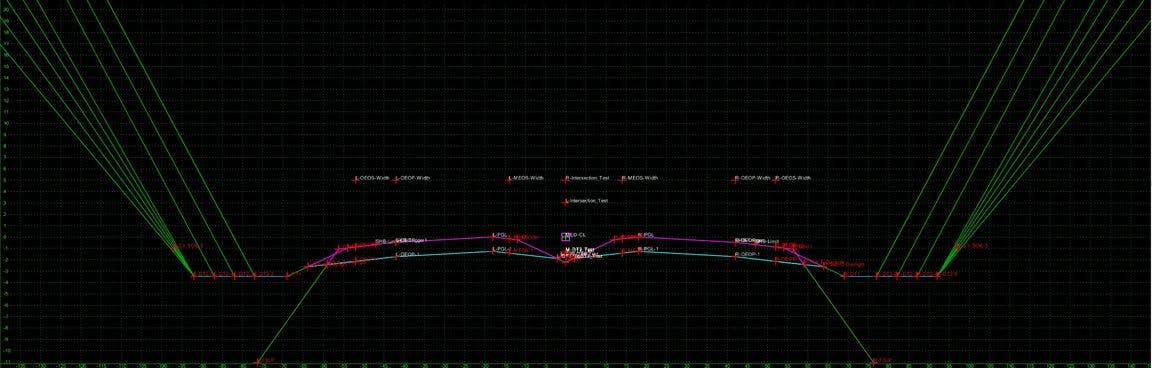

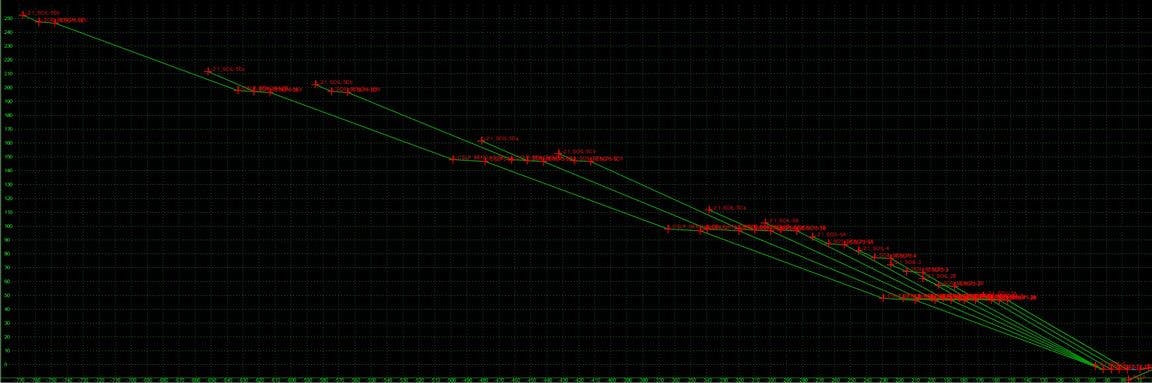

Bentley civil design software, such as GEOPAK utilizing Open Roads technology and now Open Roads Designer, is an example of one design tool that allows a designer to create 3-D models. These models are developed by creating a template that is pushed along horizontal and vertical geometry.

Figure A: Standard template backbone for Corridor H Project

Figure B: Cut Slopes for Corridor H Project

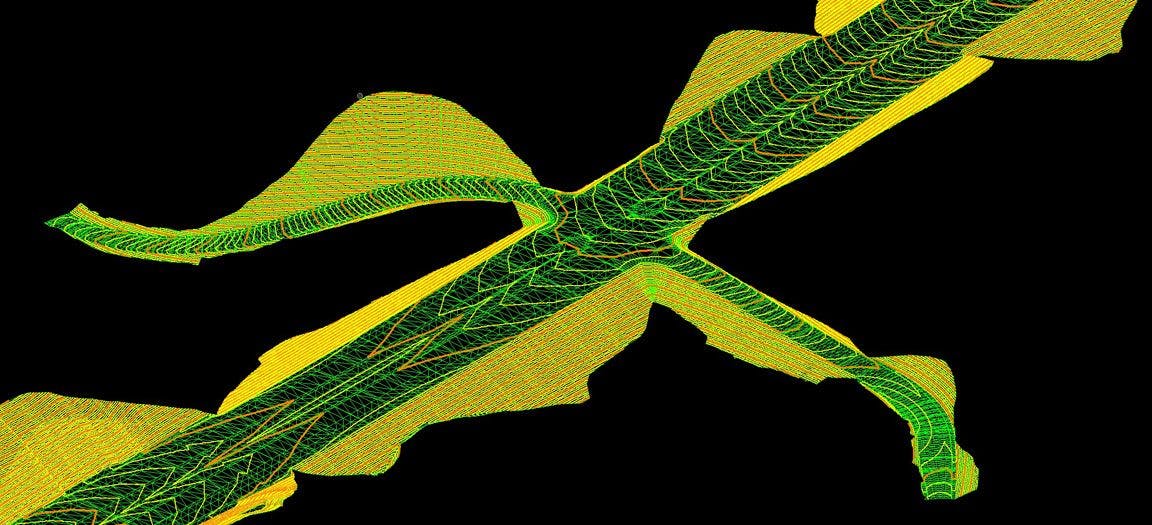

After the template has been pushed through the project, a mesh is developed that can then be extracted into several file formats (TIN, DTM & LandXML). Once that file is saved, it can be displayed visually through contours, triangles, break lines, etc. See the following figures:

Figure C: Open Roads Design Environment (Plan, 3-D, and Cross Section Views)

Figure D: 3-D Contours and Triangles of an at-grade interchange

While the contractor benefits greatly from the models, the designer does as well. 3-D modeling provides a QA/QC check that is impossible to achieve in a 2-D environment. The power of visualizing the design allows the visualization of things that may appear correct in a 2-D cross section view, but upon further 3-D review, may not be feasible or constructible. 3-D modeling can provide greater accuracy in the design process allowing the designer to push the envelope in innovation.

Back in 2007, E.L. Robinson Engineering won the first design-build project advertised by the West Virginia Department of Highways. The U.S. 35 project was a great achievement by not only winning and delivering the first ever project of its kind but also by developing partnerships between the firm and the contractor. These partnerships have developed into a formidable team with great success in winning design-build projects. This new era of design is also the start of E.L. Robinson Engineering firmly embracing 3-D modeling and becoming a known quantity of the concept within the industry.

After E.L. Robinson had finished the U.S. 35 Design build project, another such project came about in 2010 that was an additional phase of U.S. 35. This phase was much longer and in a more mountainous terrain which would require larger cuts and far more complex back-slopes. Tackling this project required a deeper look into our design process than that of the first U.S. 35 design-build. In the first project, the design process was within a 2-D environment. ELR utilized GEOPAK criteria files and manually edited line-work for the more complex back-slopes to develop cross sections and earthwork numbers that would eventually be used for bidding the project. The old method of 2-D drafting was not feasible and would limit our ability to develop an optimum design. ELR had to look to a new method of extracting the quantities needed for the bid. ELR would need to maximize the optimization of the profile design so we could position the design-build team in the most competitive position to win the project. This was the birth of 3-D design for the Columbus office at E.L. Robinson Engineering.

Using 3-D design allowed us to create templates and re-use those templates in an automated fashion. Rather than manually drafting a complex back slope on a single cross section for a single station, the model was drawn into all the cross sections at once with minor manual tweaks needed. Without modeling would mean manually drawing back-slopes for roughly half of the job’s cross sections at 50’ intervals, which would equal about 1600 cross sections for a job that was 15 miles long. This would not be feasible and would be highly inefficient. Further, this additional work effort would reduce the time available to optimize line and grade and minimize borrow and waste materials. Using the templates and automating the process, we could make changes to the profile and templates and re-run the process in a very short order; maximizing our ability to optimize our geometry design and give us the best chance at winning the project. We could then take those final proposed surfaces and use them to enhance our drainage design. By having proposed surfaces, a designer would know exactly where a drainage structure should be and narrow down more accurately the quantities assigned to the final bid. On October 26, 2010, the design build team of Kokosing Construction Company and E.L. Robinson Engineering was awarded the project with a winning bid of $187,228,00. It was a new era of design for our firm and one with great promise.

Since this time, E.L. Robinson Engineering has delivered 3-D models for the following projects:

- FRA-71-5.29

- CUY-77-13.80 CCG6

- CUY/SUM-77 Design Build

- CUY/SUM-271 Waste Area

- Corridor H Design Build

- Willow Island

- LUC-24-6.19 VE

- CUY-90-14.90 CCG2 Bike Path

We continue to design with a 3-D mindset. Not only do we provide a valuable and necessary product to our clients, but we have the ability to maximize the efficiency of our designs; limiting errors and making constructability easier. Today, more and more project scopes of work require a 3-D deliverable. Some State DOTs are even doing away with paper plans and requiring electronic models. E.L. Robinson Engineering has the known ability to deliver which improves our partnership opportunities.

https://vimeo.com/332306225