Modeling the Way to 3D

ELR Helps Drive 3D Modeling as the New Industry Standard

When the Ohio Department of Transportation (ODOT) set up a Federally-funded initiative to develop a game plan around 3D modeling for roadway design and construction, E.L. Robinson was on the shortlist to provide ideas to a newly formed committee to help make it happen. That was way back in 2014, and it was thanks in large part to our early innovation and successful track record in applying the technology to complete complicated roadway projects in West Virginia as early as 2010.

As an integral part of the ODOT 3D Modeling Committee, our team members David Barna, Barry Logan, and Kevin Fahy had the opportunity to engage in a discussion with their peers in consulting and construction; sharing ELR modeling experiences and best practices. Based on the progress of those meetings and discussions, a framework was being developed that would change the design process for the industry. Those changes included new software requirements, workspaces, and deliverables with deadlines for all consultants to make the upgrade. The overall effect will ultimately add significant efficiency to the overall system and will save time and add accuracy on a project-by-project basis.

Progress toward a fully 3D-enabled industry varies state-by-state. Some already require 3D modeling on every project, with no paper plan sets allowed. Eventually, and probably relatively quickly, all states will require it. But change takes effort and investment, and many companies are slow to evolve without incentive. That’s why it was so important for ELR to work with the State of Ohio to help bring its projects forward to the leading edge.

Moving Mountains: Early Adoption of 3D Modeling

For ELR, it was a natural progression based on the caliber and complexity of the work we do for clients. Technology is integrated into everything we do, and 3D modeling was right on the money when we needed to solve the problem of time constraints around earthwork in the mountainous terrain of West Virginia, where we do a great deal of work.

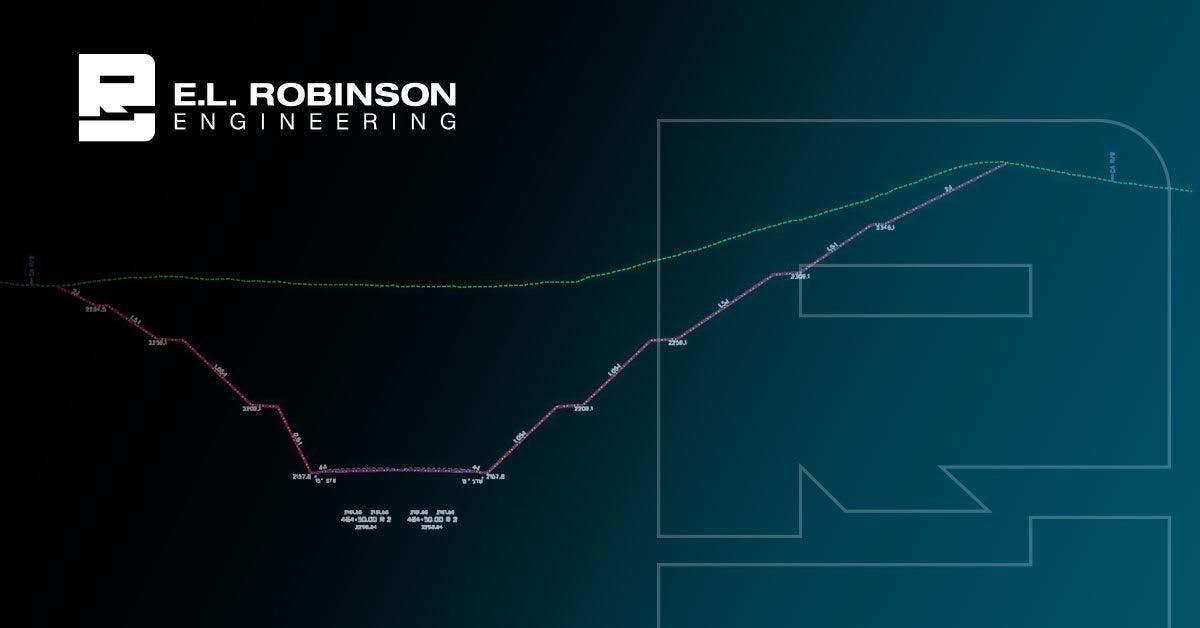

We embraced it early on as a way to create a template, or a cross-section, of the roads we were designing, to ensure the automated grading of the cut out below the road and the fill above it would be done exactly to specifications in the construction stage.

Taking another step back, it’s important to note that there are three stages to any roadway project:

- Design/Model

- Build

- Manage/Maintain

For us, stages one and two are essential. 3D modeling sits between our meticulous design and our accurate contracting/construction work in accordance with that design. The 3D model serves as a kind of physical space database. This allows us to better ensure the quality and timely completion of the finished product.

It’s a great benefit to our clients as well because it also allows us to hand off the data for stage three in the 3D model format to the future asset managers as a Building Information Management (BIM) lifecycle tool, enabling them to see changes over time and target their maintenance with precision as well.

3D Modeling All Fleshed Out

With a solid 12 years of experience in the “new” 3D modeling technology for roadway design and construction, we see another benefit. With the old method, modeling and information were stepwise - you could not get a full view of all of the layers of complexity in one image. Now we are able to see the full complexity between the plan and the result from the outset in all its detailed glory.

That’s not just helpful. It’s also a “happy place” for us as engineers. With details like that at our fingertips, we are ready to change the world, one road through one mountain at a time.

Talk to Us about 3D Modeling or Other Projects

If you want to hear more about 3D modeling or if you have a project you think we could help you with, please contact us to get the conversation started.

Please follow us and join the conversation on our LinkedIn page.