Concrete can be a hot topic

High amounts of heat are generated during curing when portland cement combines with water. This is especially true in the first few days or weeks after concrete placement. In sections determined to be mass concrete, the chemical reaction produces high temperatures at the center of the concrete’s mass due to the insulating effect of the concrete. This insulating effect traps heat, not allowing the energy to quickly dissipate. This entrapped heat causes a temperature difference or gradient between the concrete’s center of mass and the exterior surface. This temperature gradient can induce significant thermal stresses which can lead to cracking if induced tensile stresses exceed the tensile strength of the concrete. These cracks affect serviceability and can cause structural integrity issues.

The American Concrete Institute (ACI) defines mass concrete as “any volume of concrete with dimensions large enough to require that measures be taken to cope with generation of heat from hydration of the cement and attendant volume change to minimize cracking.” Codes such as the ACI Code and the AASHTO LRFD Bridge Design do not use specific size limits to define mass concrete.

At ELR, we have applied state of the art material modeling techniques (to consider the effects of heat of hydration) and FEA (using the ConcreteWorks. Software) on concrete elements to evaluate effects of thermal induced stresses and to find the maximum temperature differential on the concrete. Thermal modeling has been used to optimize concrete mixture proportions and in implementing necessary construction requirements such as insulation. These forms of analysis can result in realization of cost savings due to the elimination of unnecessary joints, allowing increased placing temperatures and reduced insulation requirements.

- The major parameters in the thermal modeling involve the following:

- Anticipated concrete placing temperatures

- Concrete surface boundary conditions (R value of insulation)

- Approximate ambient air temperatures

- Concrete mix design parameters

- Size and shape of the elements.

Our thermal modeling also includes prediction of the time period during which insulation must be in-place until the concrete cools down.

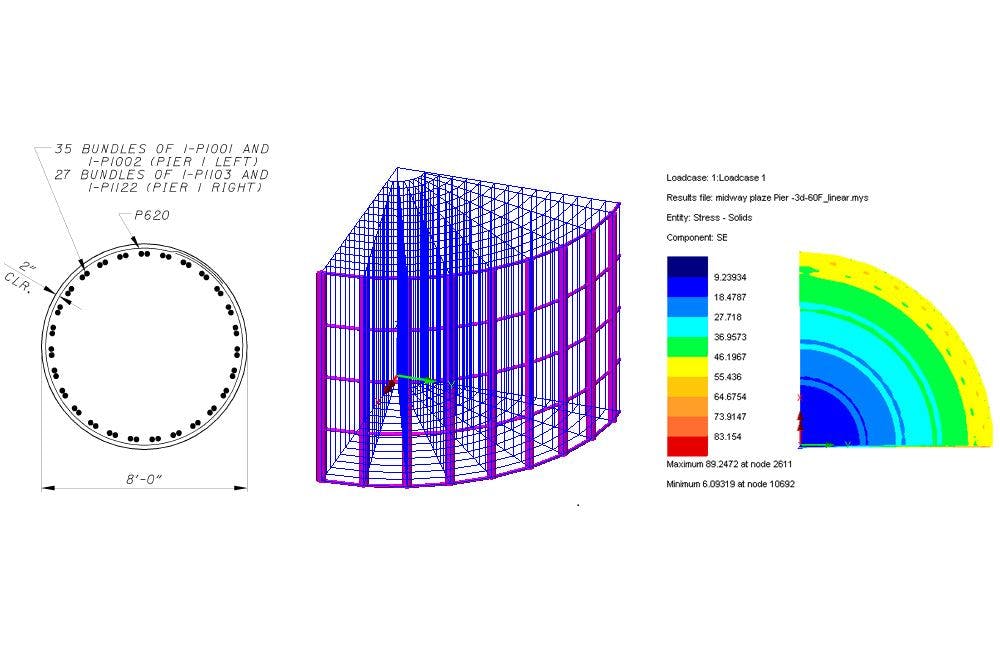

The picture above show a 3-D finite element model of a pier column with reinforcement. This analysis was performed to evaluate the influence of the differential temperature on the stresses induced in mass concrete during the hydration stage.

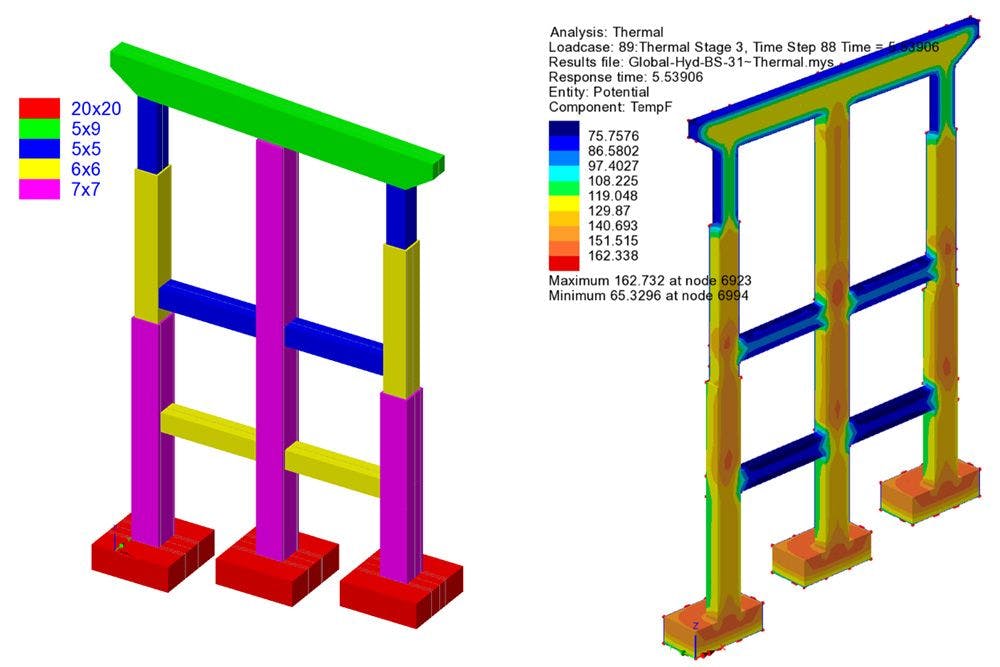

The thermal analysis for a 780 ft long 3 span bridge supported on multicolumn piers. The columns are variable in size starting with 7’x7’ at the bottom down to 5’x5’ at the top. The effects due to the addition of additives such as fly ash and slag were considered for a thermo-structural coupled analysis.

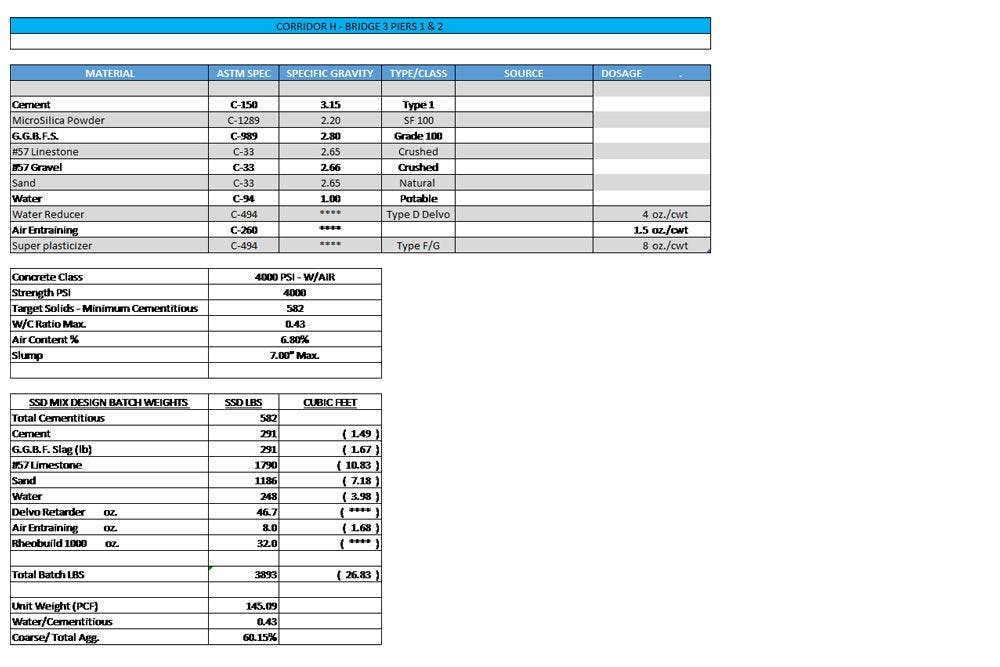

Thermal analysis inputs.

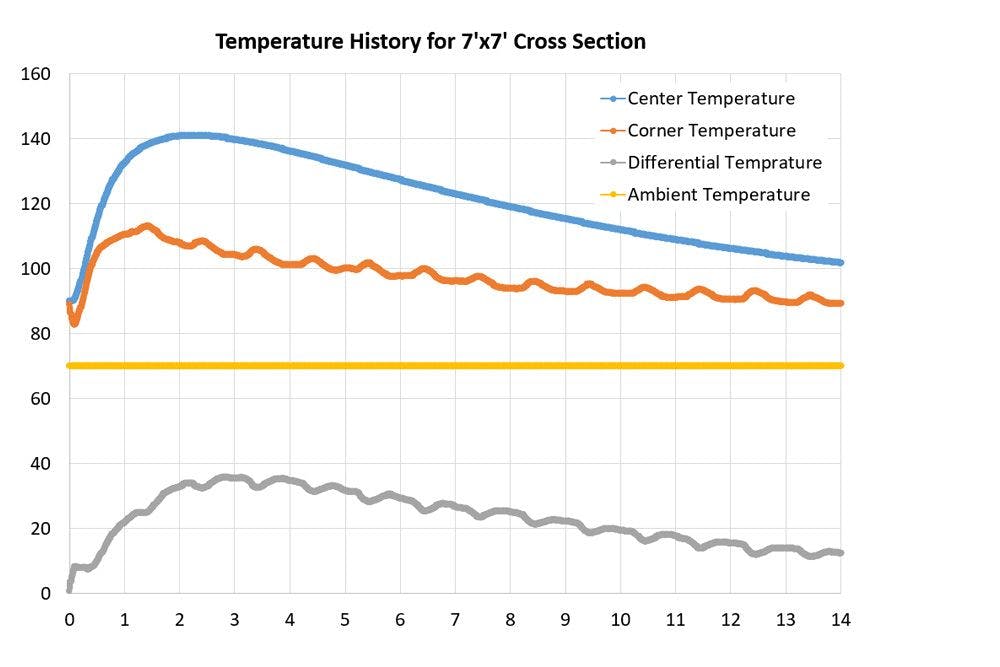

Thermal time history of 7’x7’ cross section.