Willow Island

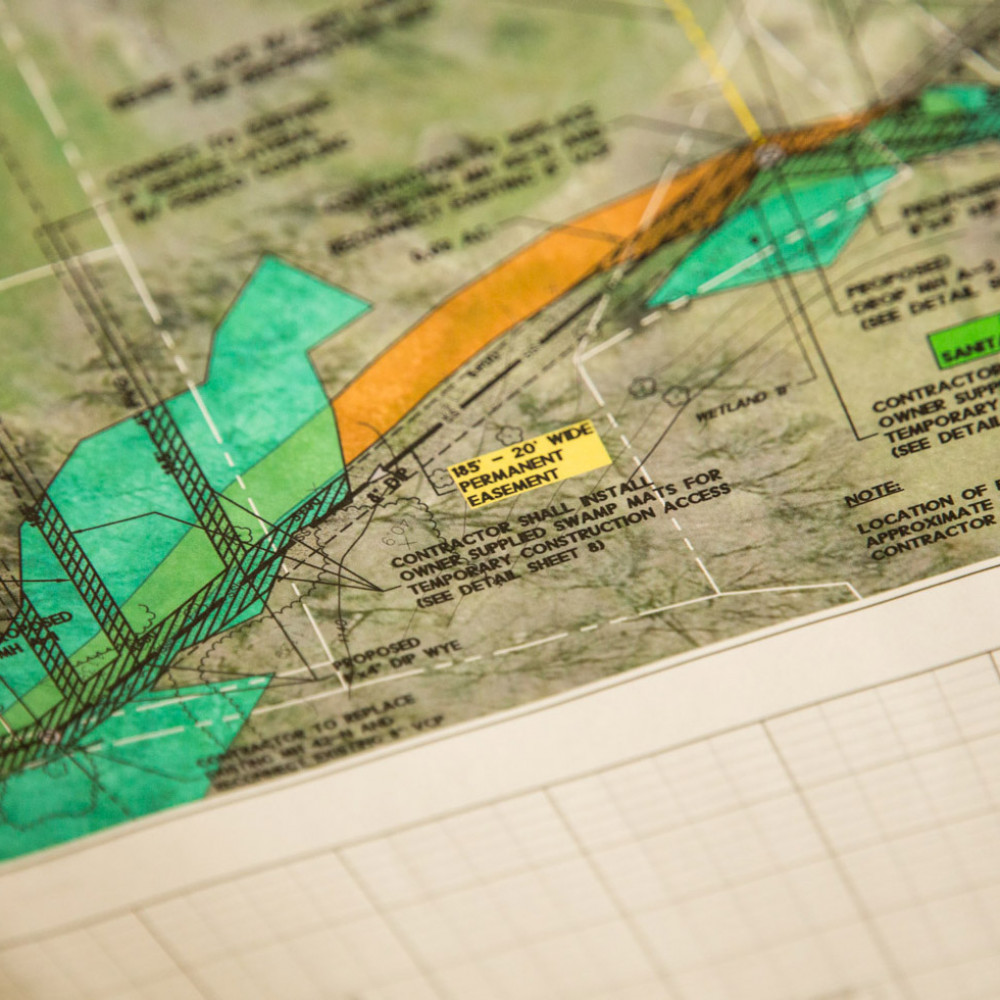

E.L. Robinson Engineering, working as the designer for The Ruhlin Company, was successful in winning the $40,000,000 Design-Build Willow Island Power Plant Site Development Project. The project, currently under construction, involves diverting water from the locks and dam through a powerhouse to generate an average annual output of approximately 195 GWh. ELR Engineering designed and coordinated the layout and arrangement of the cellular and land-slide earthen cofferdam, perimeter slurry cut-off wall, powerhouse excavation, instrumentation, dewatering system, and temporary roads.

In addition, ELR was responsible for the preparation of all design criteria, analyses and design calculations, specifications, construction drawings, and quality control and quality assurance. The design includes construction, operation, and maintenance of the necessary facilities, including groundwater seepage cut-offs, required for dewatering the construction areas, and insuring that the completed excavation is free from running or standing water. The system incorporates pumping wells, sumps and drainage ditches to allow all work within the cofferdam to be accomplished in the dry.

The design also includes an instrumentation system to monitor the performance of the cofferdam excavation and dewatering system. During the drilling for establishing the base elevations for the dam structure within the first stage of cofferdam, a fault under existing Pier 9 and weir area was discovered resulting in changes in the footing design of the pier. The fault-shattered rock was removed, excavation was cleaned and backfilled with concrete, and the concrete gravity monolithics were replaced with circular sheetpile cells and connecting arcs. Slush grouted rock berms were placed downstream for stability and a grout curtain constructed under the weir.

- Location: Pleasants County, West Virginia

- Cost: $35,100,000

- Client: The Ruhlin Company

- Services:

- Markets: